United States President Joe Biden signed an executive order on Wednesday (February 24th 2021) with the intent to boost manufacturing jobs across the U.S. while also strengthening supply chains for multiple critical production materials.

When I first heard about this executive order, my initial thoughts went back to 2010 when U.S. Congress passed Section 1502 of the Dodd Frank Act. This act required all U.S. public companies to do a supply chain audit to check for various precious metals and minerals that originated in Congo or neighboring regions.

This had a sweeping effect on the U.S. supply chain world, but overall has proven to be what was a successful first step towards ethical sourcing and risk mitigation.

Whether or not this new executive order will have the same kind of effect remains to be seen, but myself, along with the rest of the JAGGAER team, will be following it closely.

While this is, and will continue to be, a developing situation here’s everything that we know right now:

What Does the Order Mean?

The executive order itself calls for two things according to President Biden:

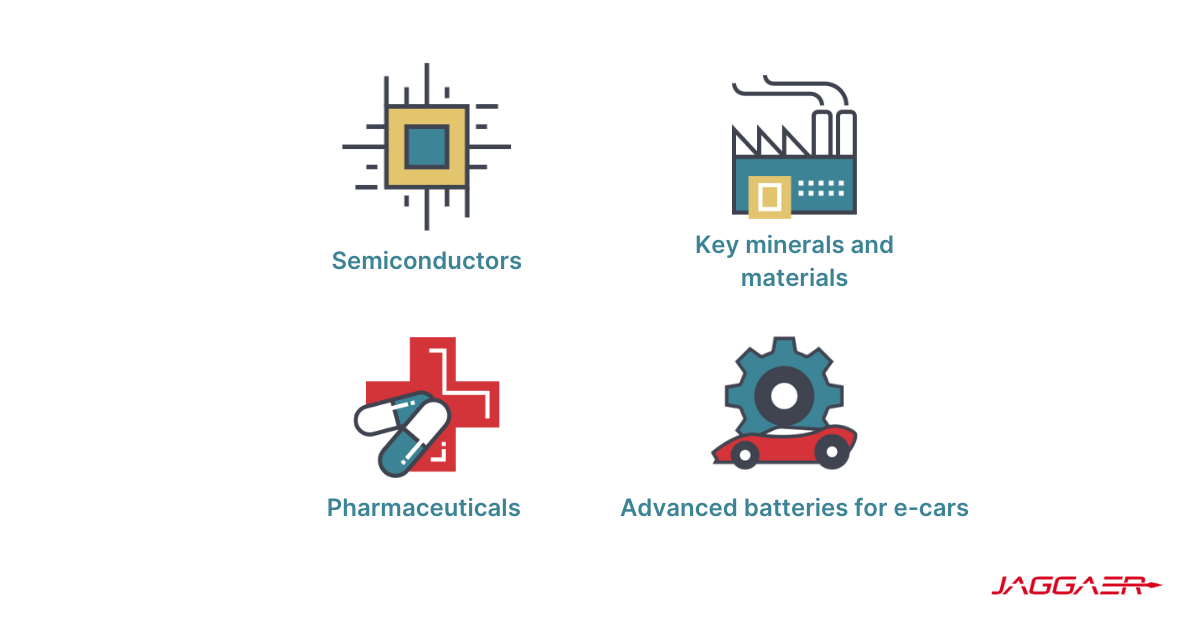

First, it orders a 100-day review of four key product supply chains: pharmaceutical ingredients, rare earth minerals, semiconductor chips and large-capacity batteries often found in the production of electric cars.

Second, the order calls for a long-term review of the supply chains in defense, public health, communications technology, energy, transportation and food production. These reviews are designed to identify vulnerabilities and provide policy recommendations to fortify U.S. supply chains.

Aside from these supply chain reviews, he also went on to talk about investing more in U.S. production of materials and decreasing the reliance on imports in some areas; the order is designed to help insulate and prepare the economy for future disruptions by making the U.S. less reliant on foreign supplies and more proactive in addressing supply chain weaknesses.

This new policy is brought on by a few reasons, most of which stem from the continuing effects of the Covid-19 pandemic on global supply chains. Earlier last year there was a severe shortage of personal protection equipment (PPE) caused when China diverted its supply to address its local needs, leaving countries heavily reliant on those imports, out of luck.

This exposed a glaring supply chain vulnerability that the U.S. government has spent the past year trying to correct.

More recently, and what this executive order directly affects, is the shortage of critical components, namely semiconductors, batteries, and key minerals used in a variety of finished goods from pharmaceuticals to airplanes.

Particularly hard hit is the automotive industry, which is reliant on the semiconductors, microchips, and, increasingly, advanced battery technology in order to manufacture vehicles. IHS Markit reports that the chip shortage has caused a loss of 1 million vehicles from being produced globally, resulting in canceling shifts, slowing assembly lines and in some cases temporarily closing factories.

Preparing Your Organization

If you operate in one of these key sectors, or manufacturing in general, you probably have a lot of questions. While there’s certainly more information to come, it’s important to start thinking about what you can do to prepare your organization’s supply chain for possible increased requirements or expectations. How can you make sure your supply chains are as resilient as possible?

A 360° View of your Supply Chain

What the pandemic, and now this executive order shows, is the need to be proactive with your supply chain strategies.

Being prepared is paramount. Macroeconomic disruptions are not exclusive to pandemics. While others may not have the world–stopping effects of Covid-19, natural disasters, financial and economic crashes, and ethical violations still pose a significant risk in nearly every industry in the world.

In order to truly be proactive and prepare for any potential risks, you need to get a 360° view of your supply chains, taking a holistic approach to supplier management.

Finding a Technology Partner

The first priority should be investing in a new technology partner that fits in your business’s strategic roadmap and can offer you the robust capabilities you need today.

A solution that can offer you a single source to onboard, house, scorecard and analyze all of your supplier data is a must.

A fragmented approach to managing suppliers is a surefire way to not only over–spend and maverick spend, but also opens you up to risks and disruptions.

Artificial intelligence and predictive analytics are already being integrate with many supply chain tools on the market and can significantly bolster your abilities to identify and mitigate potential risks and vulnerabilities, while also giving you the agility required to problem solve in the moment if need be.

An example of this is JAGGAER’s AI-based On-Time Delivery (OTD) Predictor, which can predict with 95% accuracy if an order is at risk for arriving late, even before placing the actual order.

It is virtually impossible for a human to calculate if certain categories of materials will arrive on time for a manufacturing process to proceed with any sort of accuracy. More so, this OTD predictor can arrive at its prediction in seconds, giving ample time for a procurement team to adjust course or find an alternative supplier.

Supplier Diversity

In order to build lasting supply chain resilience, you need to invest in diverse suppliers.

In the classical sense, supplier diversity means investing and cultivating relationships with women owned, black owned, veteran owned and other historically underutilized businesses.

This comes with a variety of proven benefits including cost reduction, increased agility, supply chain innovation, CSR, risk mitigation and much more.

Building a successful supplier diversity program is something that takes work, but is well worth the result.

Further still, a diverse supply base means building and furthering your strategic supplier relationships, geographically diversifying your supply chain and looking beyond your n-tier suppliers.

Decreasing reliance on a small subset of key suppliers is a large reason why President Biden has given this executive order, and it should be a key part of any successful supply chain strategy moving forward.

A Developing Situation

While we’ll surely get more clarity in the coming days about what this executive order will mean for manufacturing companies, right now we can start by seeking out areas to strengthen existing supply chains.

No matter what comes of this, one thing is clear: A reactive approach is no longer going to cut it, today’s world calls for innovation, collaboration, and a proactive strategy.

For more information regarding your specific vertical and how you can build supply chain resilience, check out these pages: