This article was co-authored by BearingPoint Life Sciences team and JAGGAER Research Material Management tool expert.

The pharmaceutical industry is highly competitive, with companies investing heavily in R&D to discover new drugs and treatments. At the core of R&D lies discovery research, from target identification to High Throughput Screening, which is subject to intense pressure and scrutiny. Within this framework, it is crucial to ensure that all scientific research-related activities such as laboratory material procurement and stock & safety management are optimized for efficiency.

This is where the JAGGAER Research Material Management (RMM) excels. A specialized platform for integrated procurement and full-life-cycle management of research materials, including chemical and biological reagents, lab supplies and consumables, RMM is a significant time and money-saver for all drug discovery labs and will revolutionize your R&D procurement.

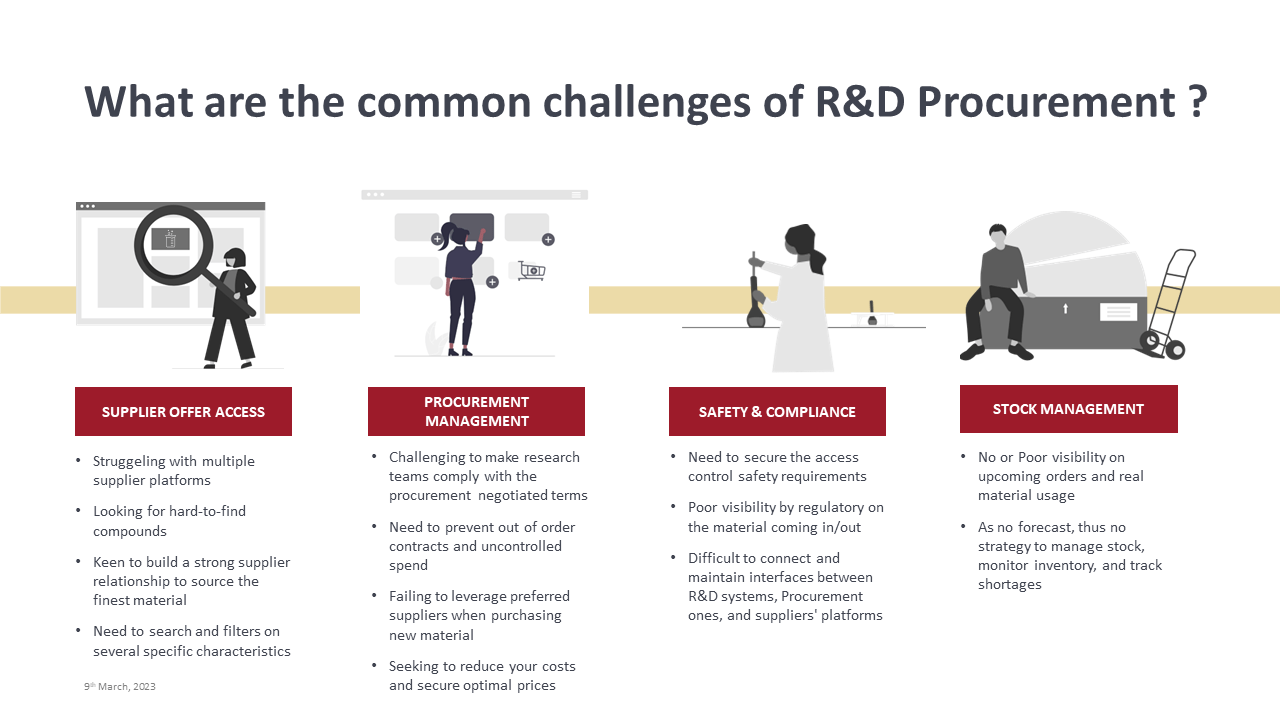

1. What are the common challenges in R&D Procurement?

Whether struggling with multiple supplier platforms or obtaining hard-to-find compounds, procurement can be a daunting task for researchers. Lab teams need to be able to conduct efficient molecule searches and filter on multiple specific characteristics (physical properties such as purity, packaging, suppliers, etc.). Moreover, it is also key to build and consistently utilize strong supplier relationships to secure access to the finest material, with high quality products, competitive prices, and reliable delivery.

R&D Procurement teams are regularly challenged when researchers fail to comply with negotiated terms, leading to out of order contracts and uncontrolled spend. Leveraging preferred suppliers is a fundamental discipline to secure optimal prices but can often be difficult for researchers to apply, particularly when it comes to specialty materials for unique research needs.

Ensuring product safety and compliance is another critical aspect of research material procurement. Access control and safety requirements must be secured all along the product life cycle, and regulatory visibility on material coming in and out is an obligation for certain compounds. Audit considerations mandate the application of regulations and reporting consistent with standards applied to inventory reporting. If a compound in inventory is flagged as a controlled substance, then its purchase request must also be flagged, regardless of whether its supplier identified the item as controlled.

Additionally, lab stock management can be a significant burden for organizations due to poor visibility on upcoming orders and real material usage. The uncertainty and unpredictability of discovery activities make it challenging to forecast lab material needs. Without accurate predictions, formulating a stock management strategy can result in unreliable lab material budget planning and poor stock management.

Do any of these challenges sound familiar to you? How can you ensure effective procurement management, with strong supplier relationships that also addresses all researchers needs?

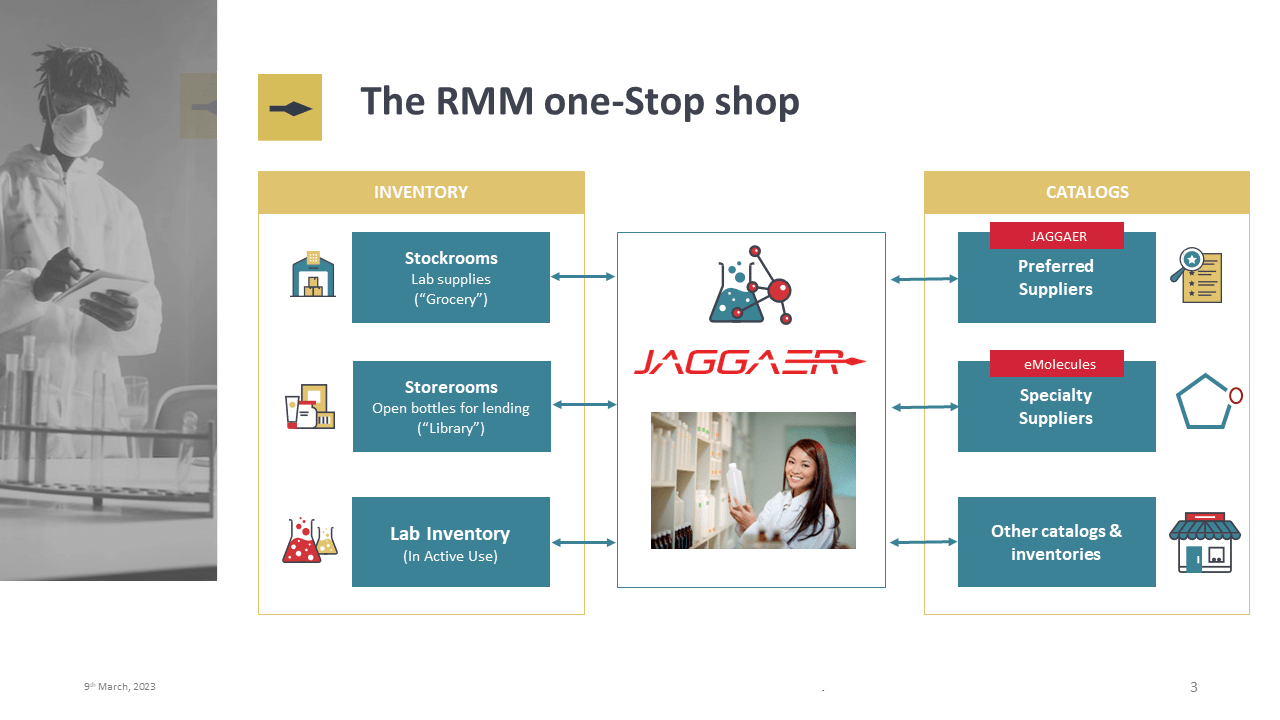

2. JAGGAER Research Material Management (RMM): your one-stop-shop for an efficient R&D procurement journey

The key to the JAGGAER RMM platform lies in its ability to capture and provide real-time material availability for researchers, within a single search, regardless of whether it is the vendor’s stock or the in-house supply.

Here is a closer look at the procurement cycle steps of JAGGAER RMM. Picture yourself through each of these steps and phases:

PRE-ORDERING PHASE:

- Material Sourcing and Searching: In the RMM platform, you can search by chemical structure or text criteria, filter on a multitude of characteristics and consult all your preferred suppliers at once. You will not only see which vendor offers the compound at the best price and delivery date, but also if it is already in stock in your lab with details on the exact location. For bioreagents, RMM partners with CiteAb, empowering researchers to make the best selection from thousands of available options, and then source selected products from preferred suppliers or inventory where possible. RMM allows you to avoid redundant purchase, to promote preferred suppliers and negotiate better deals.

Generally, JAGGAER’s clients can achieve savings of up to 20% of their research material expenditures.

- Request: The requisition process enhances compliance by presenting information such as hazardousness, price, and availability during purchasing. RMM helps you monitor quantity limits and define the need for special receiving

- Approval and Ordering: RMM integrates with your existing procurement infrastructure and processes for compliance and efficiency, supporting approvals in both RMM and procurement. For example, regulatory and safety concerns can be resolved in RMM before items enter the procurement workflow, where they follow organization review requirements for spend planning and management.

POST-ORDERING PHASE:

- Material Reception: The RMM platform fully incorporates the reception process and includes best practices for tracking acquisitions, using request data to eliminate redundant data entry. The reception can be classified as either partial or complete, allowing for the possibility of item substitution, and enables supplier follow up and accountability.

- Supplies and Consumables Management: To avoid shortages, the system supports replenishment for multiples operating models, incorporating central and point-of-use management and access.

- Material Tracking and True-up: RMM offers monitoring and reporting of restricted and regulated materials, tracks licenses (such as the radioactivity license), expiration (including for hazardous peroxide formers) and keeps watch on accumulation limits and other safety and regulatory

- Material Disposal: RMM allows consumption reporting to improve visibility into inventory levels and usage patterns. The entire disposal process is supported, from waste pickup through accumulation and manifest for off-site transportation.

We invite you to watch a brief demo of JAGGAER RMM in our Webinar Replay (starting at the 10th min) available here. In addition, you will find in this replay an insightful first-hand account from an AstraZeneca researcher who uses JAGGAER RMM today.

3. Implementing JAGGAER RMM for your Lab: what are the critical considerations?

JAGGAER RMM is a highly adaptable solution that can be tailored to fit your company’s specific needs, including roles, workflows, and systems. RMM could be implemented in your lab within 3 to 9 months, depending on the number and complexity of your integrations, on the maturity of your processes and on the change management strategy required for your teams.

- The first step to implement JAGGAER RMM would be to understand your eProcurement Core Model. The scoping phase is the opportunity to have a thorough review of your company procurement processes: are they the right ones? Do you want to change or optimize them? Is there already a core model? A mapping of your architectural environment must also be done to determine which existing applications will need to be integrated within the RMM (research applications, legacy systems to merge, API to build with procurement software like Coupa, Ariba…).

- The roll-out strategy of RMM should be adjusted to your needs and to your organizational structure. Should RMM be deployed based upon regional operations, such as the European Union, USA, Asia, or would it be more relevant to deploy RMM based on department and business units, or even by lab?

- Many data sources and legacy systems will be feeding your RMM. A crucial step is therefore to focus on data migration to ensure continuity of your R&D supply during integration and maintaining data accuracy during production

- The implementation of JAGGAER RMM is suitable for an agile or semi-agile methodology, in a short time frame and at a sustained rhythm for a high stakeholder engagement within your R&D teams.

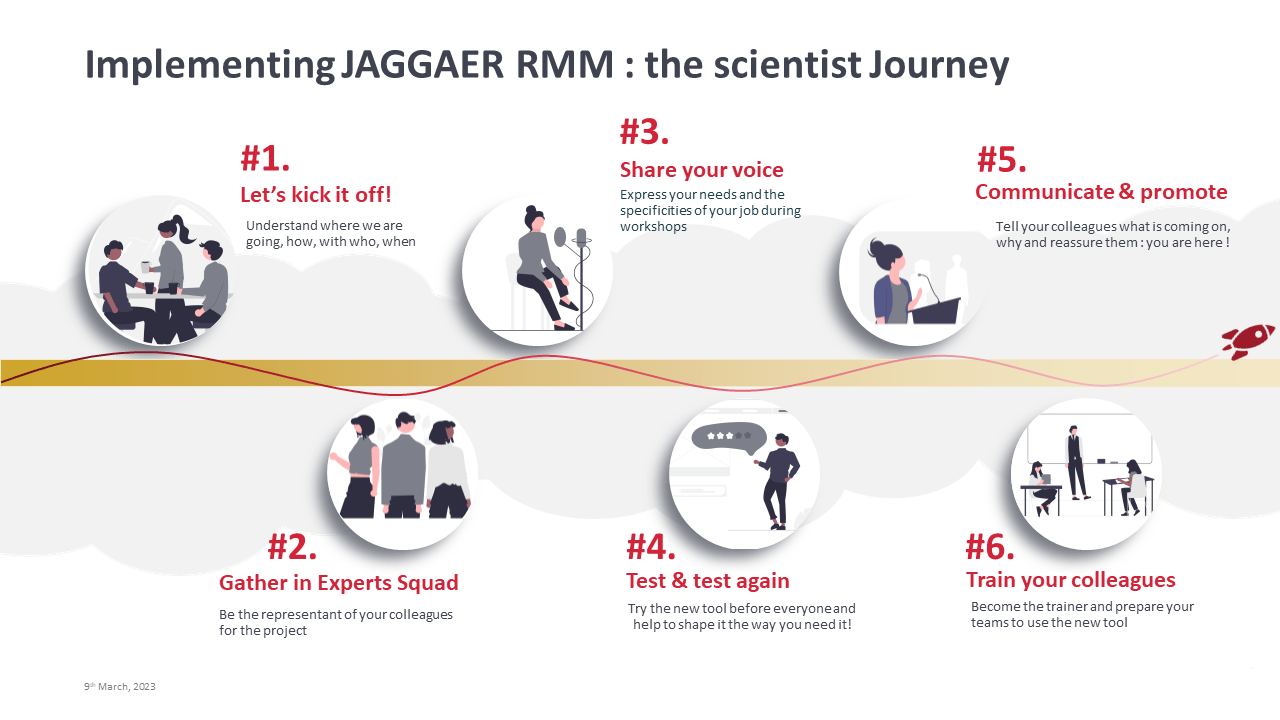

- Finally, your implementation project must be supported by a solid change management plan (see Figure 3.) adjusted to your lab and your audience. How do you create a sense of urgency to change? How do you engage your teams along the entirety of the project? How do you anchor a sustainable new way of working in your procurement activities?

BearingPoint is proud to be an official partner of JAGGAER, leader provider of procurement software & solutions for several years now, with plenty of success stories implementing Procurement & Source to Pay solutions for our clients.

BearingPoint Life Sciences & JAGGAER are sharing their common knowledge of R&D and strong experience in large & small pharmaceutical companies to provide you with the best combination of innovation & technological capabilities. By collaborating with us, you can be assured of receiving the best value for your RMM solution implementation.

Do not hesitate to contact us to learn more about RMM!

Authors: