As the COVID-19 virus begins to subside in many parts of the world, supply chains are stabilizing. Some remain unpredictable, but many companies are trying to navigate the reopening process. Once they’ve taken immediate action, how can organizations ensure stability moving forward? What mid-term steps can they take to minimize their risk and maximize value?

Companies should prioritize a few key steps to set their business up for continued success. Procurement teams can lead the way in building a robust system into the future.

Revise Your Contracts

One important step for mitigating losses and building the future is evaluating your contracts. According to the Financial Times, over 3,300 suppliers in China received force majeure certificates in February alone. This should serve as a wake-up call for procurement teams to take a look at the clauses in their contracts. For those with general or vague clauses, now is the time to rewrite them so that specific events are accounted for and there’s clarity on expectations should a second wave of Coronavirus emerge. It’s also important to develop recovery plans with your suppliers and make sure that they’re clearly outlined in contracts. Unfortunately, many organizations have thousands of contracts to examine. Procurement and legal teams need well-prepared, highly organized document management systems to systematically look at force majeure clauses are written.

Get expert recommendations on how to best navigate the current global supply chain challenges. #supplychain #sourcing https://t.co/CLYS0j4lBV pic.twitter.com/40kHrnlbvY

– JAGGAER (@JaggaerPro) April 30, 2020

There are plenty of other questions to ask yourself about your contract terms, too. First, what terms can you renegotiate right now? If there are areas of your agreement that you already know will not be met or won’t be necessary for 2020, now is the time to evaluate them and make appropriate revisions with your suppliers. You may also find opportunities for savings or improved relationships with your suppliers due to market shifts. For example, the market price of goods may have dropped and you’ll want to take advantage. Or perhaps you can use incumbent suppliers for different goods in order to maintain your relationship through the crisis.

A full digital contract management suite can help with each of these tasks. In particular, artificial intelligence or machine learning can empower the system to run contract analysis in seconds. Save your team countless hours and free up their time to work on other recovery efforts. Plus, these tools can integrate into supplier management systems to combine contract results with other risk assessment factors.

Connect Suppliers Digitally

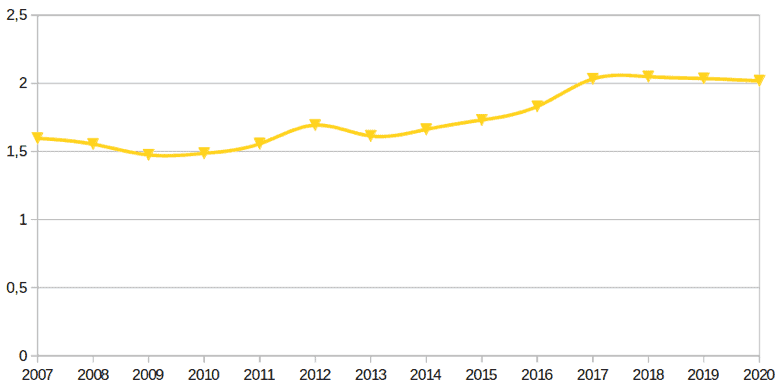

Quick communication with suppliers is key when the situation is evolving quickly. Procurement teams need to be able to make decisions rapidly and relay them to suppliers immediately. During the 2008 financial crisis, manufacturing companies decreased production. However, even as their order volumes decreased, the number of line items remained the same. The production capacity decreased, but the breadth of items being made remained steady, so the same parts were needed from the same suppliers. We’ve seen similar patterns with COVID-19. As workers are furloughed and manufacturing plants temporarily close, production slows. As a result, volumes of orders are fluctuating significantly. It’s vital to be able to communicate these changes proactively to suppliers.

It’s equally important for suppliers to be able to quickly communicate changes to you. In some cases, this might be an inability to deliver on time. You’ll want to know as soon as possible if that’s going to happen. Conversely, as suppliers ramp back up, they’ll be able to communicate quickly that parts or items are available again. As we emerge from the shutdown, having clear communication is vital. A full digital supplier management system offers the possibility to streamline these communications. A supplier portal lets you push updates and communicate securely as changes occur.

Use an Agile Implementation Approach

As the world emerges from the COVID crisis, you’ll need to be able to ramp up quickly. As manufacturing begins to speed up again, demand will skyrocket and suppliers will struggle to keep up. You’ll need to be able to alter your supplier forecasts at the drop of a hat, and a digital solution will enable that.

On agile implementation program can deliver faster results to get you up and running quickly. Just as importantly, it sets user expectations at a realistic level, setting up the system for quicker adoption and higher rates of use. By rolling out the software incrementally and continuing to revise it based on needs, you can begin working with it sooner and better tailor it to your team’s preferences over time. This gives you a platform to start working with suppliers right away.

Plan for Recovery

As we move toward recovery, you need strategies for getting your supplies as quickly as possible. When all customers have high demands, suppliers may become overwhelmed and be unable to deliver on time. As a result, it may be necessary to find alternate means of supply. First, look toward local suppliers. If they are doing business locally, there are fewer factors, like transportation capacity or customs, to create disruptions. They may also have discounts for local businesses, or business guidance to prioritize local customers. Second, consider make-versus-buy decisions. It may make more sense to temporarily look to buy completed parts rather than manufacturing them. Conversely, you may be better off making items that are unavailable from suppliers. Finally, look for new sources of supply now, before you need them.

The most important thing is to remain flexible. Each of these strategies will require your organization to move quickly and to make in-the-moment decisions. With a full digital solution, you can back up these decisions with hard data and be more confident in your choices. Be prepared to make fast adjustments. By taking these few steps, you can set your business up for success as the world begins to return to normal.

For more on how you can adapt your procurement strategies in the wake of COVID-19, take a look at our COVID-19 Response Checklist.