It’s actually quite obvious. In many industries, procurement is responsible for managing significant budgets – which means it holds a key lever for business performance. Yet it’s still not commonly perceived as a true driver of value. This is mainly due to historical reasons.

From Order Fulfillment to Strategic Value Creation Partner

This realization is relatively new and comes with a fundamental shift in how the role of procurement is understood. Looking back just 30 years, procurement was mainly seen as an ordering department. Today, its responsibilities go far beyond transactional tasks. Procurement teams now include specialists such as category managers with deep market knowledge who drive sourcing events and significantly impact the company’s bottom line.

But the procurement transformation journey is far from over. Procurement professionals are increasingly evolving into strategic value creation partners. This means that, beyond cost savings, they can also influence the top line. A prime example of this is sustainability: since a large portion of emissions lie within the supply chain, procurement holds a crucial lever here – think Scope 3. Additionally, the right measures can help shorten time-to-market. Through smart sourcing, procurement can help accelerate R&D processes and enable faster delivery of new products or solutions.

Identifying and Strengthening Potential

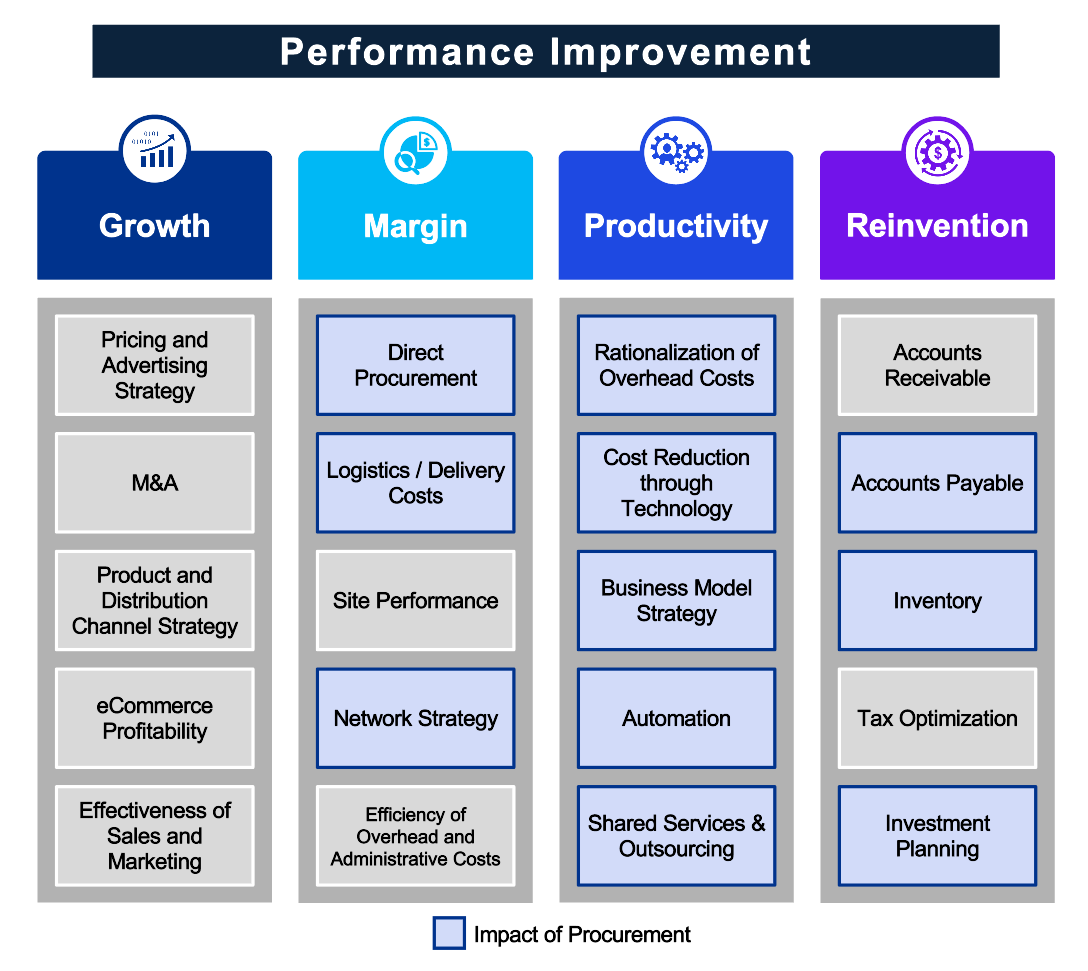

All these levers and more can be illustrated using an ideal model. At KPMG, our performance improvement programs focus on four pillars: Growth, Margin, Productivity, and Reinvention.

The graphic above highlights in blue the areas where procurement can make an impact – and they are substantial. Just a few examples:

- Procurement’s core value has always been to reduce costs – particularly in sourcing production materials.

- Procurement teams can also optimize operational activities through shared services or outsourcing.

- Proper orchestration of supply chains enhances corporate resilience.

- Procurement can influence logistics costs through tendering and smart negotiation.

- In procurement, automation supports compliance with standardized processes – boosting productivity.

In short: when procurement becomes a strategic value creation partner, it significantly contributes to enhancing business performance. This is achieved through the three key boosters: processes, organization, and technology.

Booster 1: Exploring Opportunities to Improve Processes

There are numerous opportunities to optimize processes: harmonizing and standardizing them enables better spend management. Today, it’s no longer just about selecting suppliers with the best fit and price-performance ratio. It’s equally important to partner with suppliers who use resources responsibly and contribute to sustainability goals. That’s why it’s more worthwhile than ever to consider when dual sourcing might be appropriate. One essential factor here: building partnerships on an equal footing. Supplier workshops and lean management methods help vendors work more efficiently and, through closer collaboration, strengthen mutual innovation capacity.

Booster 2: Structuring the Organization Effectively

In terms of organizational setup, it may be wise to use shared service centers for operational tasks or, thanks to process standardization, outsource parts of the work. This creates capacity to focus more on the exciting topic of purchasing strategy – not just strategic sourcing, but the overall approach to procurement. Especially in times of global geopolitical shifts, it’s crucial to provide category managers with strategic frameworks. These are essential for achieving resilience and helping category managers meet their goals.

Booster 3: Leveraging Technology Across Departments

From our perspective, the third major lever is technology. It enables broad automation of indirect procurement. In direct spend, digitalization also improves supplier collaboration – for example, by sharing forecasts to secure supply chains. It also opens opportunities to generate cost savings through optimized tendering methods.

Hand in hand with process orchestration comes the use of artificial intelligence. First-generation AI-powered chatbots are being followed by intelligent agents that support individual process steps autonomously. However, one risk with technology lies in creating new information silos through isolated solutions. That’s why I believe it’s critical to use integrated procurement platforms like JAGGAER. These not only embed AI into processes but also make it possible to scale and roll out standardizations globally.

Driving a Successful Transformation

A performance management program offers numerous levers to make the most of procurement budgets. But if you’re thinking, “We’ll implement a performance improvement program, and success will follow automatically,” think again. A KPMG analysis of 150 transformation projects revealed an important insight: we examined their effects on EBITDA and average revenue growth. The surprise? Only 27 percent of projects had a positive impact on both revenue and EBITDA. The rest either failed altogether or achieved results at the expense of growth or profitability.

That’s why it’s not enough to just identify levers and set goals. It’s equally important to evaluate planned actions in terms of cash flow and EBITDA. This is the only way to identify value-adding opportunities and avoid project risks. There are many proven best practices and models to support this – one example being the value driver tree.