The REVolution Begins With You

Unleash AI for Procurement Excellence

Elevate Your Direct Procurement Strategy & Build Supply Chain Resilience

Explore the latest reports and checklists designed to revolutionize your direct procurement and supply chain strategies.

JAGGAER Recognized Again in 2023 Gartner® Hype Cycle™ for Artificial Intelligence

JAGGAER Recognized Again in 2023 Gartner® Hype Cycle™ for Artificial Intelligence

Mentioned, for the 3rd year in a row, as a sample vendor in the Gartner® Hype Cycle™ for Artificial Intelligence, 2023, JAGGAER is the only S2P provider included in the report.

Understand how we can address your procurement challenges

JAGGAER positioned as a Leader in the 2022 Gartner® Magic Quadrant™ for Procure to Pay Suites for the fifth straight year!

Gartner® Hype Cycle™ for Artificial Intelligence, 2023

JAGGAER is again named a Sample Vendor for Intelligent Applications, learn what that means for you!

Gartner does not endorse any vendor, product or service depicted in its research publications, and does not advise technology users to select only those vendors with the highest ratings or other designation. Gartner research publications consist of the opinions of Gartner’s research organization and should not be construed as statements of fact. Gartner disclaims all warranties, expressed or implied, with respect to this research, including any warranties of merchantability or fitness for a particular purpose.

Disclaimer: GARTNER and Magic Quadrant are a registered trademark and service of Gartner, Inc. and/or its affiliates in the U.S. and internationally and are used herein with permission. All rights reserved.

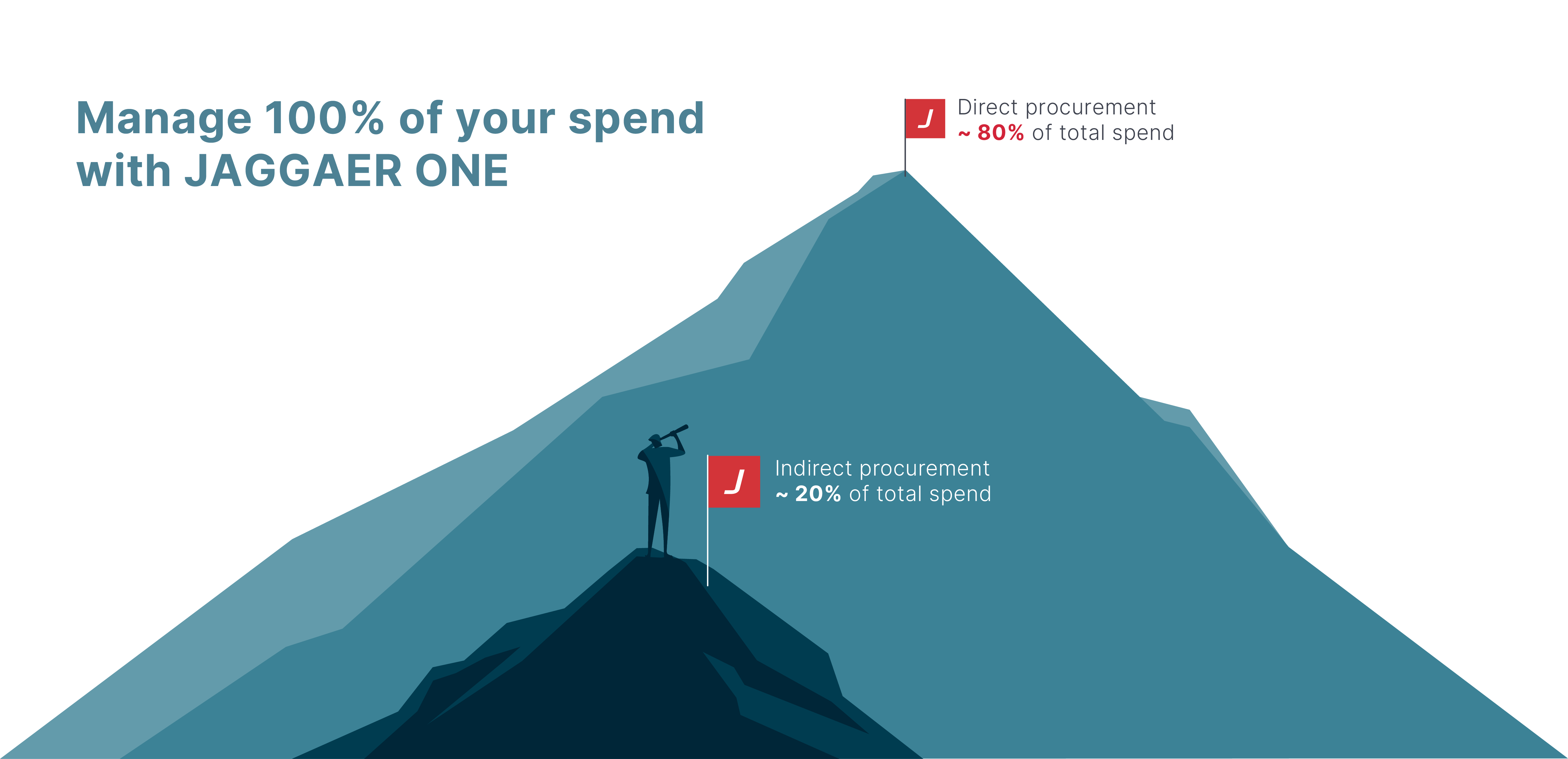

Our Enterprise Commerce Network, enabled by our Procurement Platform fundamentally transforms the way you buy, sell, and partner.

Contact us

JAGGAER ONE:

Spend Analytics

Identify savings opportunities and grow revenue with an analytics solution.

Category Management

Increase ROI with a strategic approach to managing your high impact categories.

Supplier Management

Deeper and more insightful supplier relationships with an intelligent supplier management solution.

Sourcing

Deliver the best products and services to your users while reducing costs on both sides.

Contracts

Delight your users with faster contract execution, increased compliance and decreased risk.

eProcurement

Guide your organization’s spend to compliance in a powerful marketplace.

Invoicing

Boost efficiency, optimize cost and gain control over invoicing.

Inventory Management

Track and manage stockroom inventory directly in your eProcurement solution.

Supply Chain Collaboration

Modernize your collaboration with direct material suppliers with a completely digital SCM solution.

Quality Management

Reduce supply chain risk and costs with a digital solution that streamlines your processes.

JAGGAER ONE will give us transparency and knowledge about our daily business.

JAGGAER by the Numbers

The world’s leading independent spend management company.

Centralizing procurement and implementing JAGGAER put the college into the mindset of sensible purchasing.